Blog

Future-Proofing Commercial Buildings with Smart Construction Practices

Changing Demands for Modern Commercial Spaces

Commercial building designs have transformed dramatically over the past decade, reflecting global work trends and the necessity for more adaptable and health-conscious environments. Today’s tenants seek flexible, future-ready spaces that accommodate work-from-anywhere policies, on-site wellness initiatives, and seamless connectivity. Owners and developers must keep pace, not just responding to what tenants want but anticipating how those needs will evolve in five or ten years. Choosing forward-thinking construction partners like Guaranteed Contractors is a strategic advantage. These specialists apply experience and innovative planning to create environments prepared for shifting workplace culture, fluctuating occupancy levels, and ever-changing safety protocols.

Flexibility has emerged as both a demand and an opportunity. Spaces that can be quickly reconfigured, resized, or repurposed make commercial real estate more valuable in fast-changing markets. Many developers now view smart technology investments as critical tools for delivering this adaptability while keeping operational costs low, especially during uncertain economic periods. These innovations are increasingly the foundation for resilient, attractive properties that stand out to long-term tenants.

Core Principles of Smart Construction

At the heart of any successful innovative construction project lies the seamless marriage of technology with intentional design. Modern commercial buildings are protected shells and interactive platforms where the core infrastructure can sense, learn, respond, and evolve. Five main pillars support this next-generation approach:

- Smart system integration — Centralized control systems seamlessly manage lighting, HVAC, security, and building access. This coordinated infrastructure allows facility managers to adjust comfort levels or respond to emergencies with just a few clicks, improving operational efficiency and tenant comfort.

- Connectivity — High-speed, building-wide wireless networks support diverse devices and sensors, generating constant data about building performance and occupant needs. This real-time intelligence lets managers optimize energy use and predict potential issues before they cause disruptions.

- Flexible layouts — Smart spaces are designed from the ground up to accommodate evolving floor plans, modular furnishings, and movable walls. This level of adaptability ensures a building remains marketable whether the tenant is a creative startup, a call center, or a medical practice.

- Security and privacy — Next-gen surveillance, access control, and cybersecurity protocols work together to secure the physical and digital spaces within a building. They foster tenant trust, which is crucial as more business processes move online.

- Sustainability — Environmentally conscious choices are integral to modern construction. These include solar readiness, efficient climate control, and water-saving features that create measurable benefits for owners and occupants.

Integrating these principles from concept through execution is crucial for buildings to be truly “future-proof” and competitive in any market landscape.

Advances in Energy and Building Technology

New technologies are bringing a revolution to how buildings use and manage energy. Smart meters track real-time electricity, gas, and water use, enabling immediate adjustments to eliminate waste. Cloud-based controls link every light and HVAC vent to a central dashboard, allowing fine-tuned scheduling and monitoring from a smartphone or command center. Even daylight harvesting—automatically adjusting artificial lighting levels based on sunlight—is becoming mainstream, enhancing occupant comfort while cutting costs.

Air quality and comfort control systems are now responsive, using occupancy sensors, carbon dioxide monitors, and temperature detectors to ensure the healthiest, most productive indoor environments. Major studies show that buildings employing these energy management technologies can achieve remarkable reductions in energy consumption, often upwards of 20% to 30%. This is not for the bottom line, butigns commercial assets with urgent global climate goals and increasingly stringent building performance standards.

Sustainability: Building for Tomorrow

In the current construction landscape, sustainability is as much a competitive edge as a social duty. Green construction goes far beyond recycling bins—using high-performance insulation, triple-pane windows, and low-impact flooring materials to reduce emissions and improve durability. Intelligent irrigation systems, water recapture units, and even green roofs are being integrated into commercial sites to offset resource use further and boost building longevity.

Environmental certifications like LEED, WELL, and Energy Star aren’t just public relations talking points. These accreditations attract sustainability-minded tenants, unlock government incentives, and can even reduce insurance premiums. Over the long term, they help commercial properties outperform peers on utility expenditure, tenant recruitment, and reputation, creating cyclical value that extends to every stakeholder.

Cutting Costs and Boosting Value through Smart Solutions

From a business perspective, the financial benefits of innovative construction can be substantial. Connected controls allow asynchronous heating and cooling based on occupancy, reducing waste in unused areas and extending the life of expensive systems. Automated alerts enable facility teams to catch and fix issues—such as water leaks or temperature anomalies—before they generate costly repairs or disrupt tenant business operations.

Commercial real estate outfitted with high-tech infrastructure consistently commands higher rents and experiences lower turnover. As data-driven solutions become the norm, properties with well-executed innovative systems will also see improved insurance evaluations and greater appeal to forward-thinking investors. Ultimately, adopting innovative solutions is a pragmatic way to future-proof not just the structure, but also the business model behind any commercial property.

Case Study: Real-World Example of a Smart Building Upgrade

Consider a mid-century office tower in a bustling downtown business district. The building owner invested in a transformative retrofit when facing declining occupancy and rising utility costs. New networks of sensors connected to centralized software allowed real-time control over lighting, HVAC, and even elevator operation. The project team also installed automated air quality monitoring to maintain optimal environments—a massive win for health-conscious tenants.

Within the first year of operation, the building’s total energy consumption dropped by 25%, and tenant satisfaction surveys showed a marked increase in comfort and convenience. Tenants noted improved lighting quality, faster response times for maintenance tickets, and better quality. The building became a destination of choice in its neighborhood, attracting technology-driven organizations drawn to modern amenities and sustainable design.

Why Collaboration Matters in Smart Construction

The complexity and sophistication of modern innovative building projects demand real teamwork across roles and disciplines. Architects, engineers, IT specialists, contractors, and maintenance teams can collaborate openly from the earliest planning stages. Early-phase workshops, digital modeling, and frequent feedback loops keep the entire team on the same page and help manage evolving expectations efficiently.

Crucially, involving end-users—such as facility managers and tenants—leads to more brilliant, practical technology choices. Their insights drive user-friendly installations, intuitive controls, and spaces that cater to real organizational needs. By focusing on collaboration, teams create buildings resilient to technological change and shifts in how people work and interact within shared spaces.

Future Trends: What’s Next for Commercial Buildings?

The next era of commercial construction is poised to bring even greater changes. Artificial intelligence will refine how building systems predict and respond to daily patterns, from finely tuned heating and lighting adjustments to real-time occupancy tracking. Resilience to technological change and reality for remote troubleshooting are now appearing in leading developments, offering cost savings and improved safety.

Digital twins—sophisticated 3D models that mirror every physical characteristic of a structure—will enable property teams to simulate scenarios, manage assets, and plan upgrades virtually, significantly improving decision-making and predictive maintenance. Industry standards are moving toward more open, interoperable platforms, allowing seamless upgrades as new technologies become available. Staying informed about these trends and working with teams dedicated to innovation is the surest way to ensure each building delivers long-term value for owners and those working inside.

By embracing innovative construction and emphasizing adaptive, collaborative strategies, businesses and developers will create the next generation of commercial spaces that promote comfort, wellness, efficiency, and sustainability in equal measure.

Blog

Modern Real Estate Trends Shaping Residential Living

Today’s residential real estate market is undergoing a dynamic transformation, driven by technological advancements, evolving work habits, and shifting lifestyle preferences. Buyers and renters increasingly seek homes that accommodate remote work, technological convenience, and environmentally friendly designs. These modern shifts are evident in thriving markets such as Aspen, where high-end living intersects with the latest housing trends. For those interested in premier properties designed with today’s standards in mind, explore Aspen Homes for Sale for a glimpse of homes that embody these progressive features.

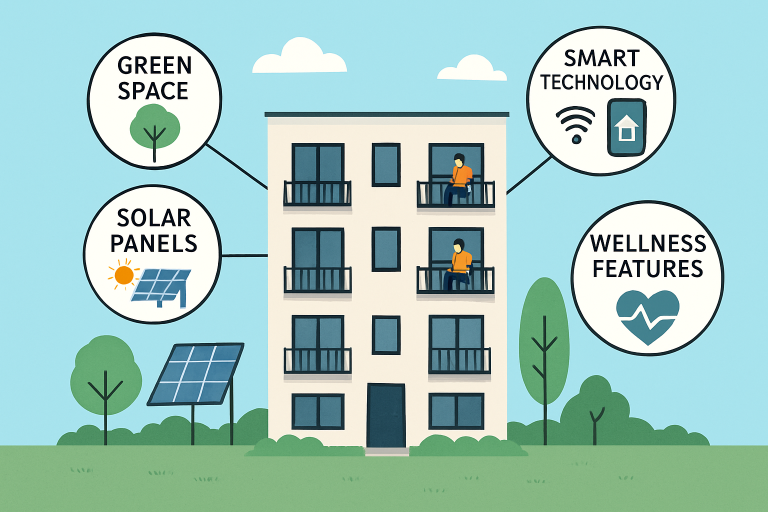

Whether looking for a high-rise apartment with wellness amenities or a smart home with energy-saving technology, consumers now demand flexibility and innovation. Factors such as sustainability, community-oriented living, and digital engagement play pivotal roles in how developers design and market new residences, shaping the future of where and how people live in both urban and suburban areas. With market pressures and environmental concerns, homebuilders prioritize innovations that increase efficiency and foster community. This holistic approach enhances property values and residents’ well-being. In leading cities and luxury destinations alike, these trends are steering the market toward greener, smarter, and more connected homes.

Staying ahead of these shifts is crucial for both buyers and industry professionals. According to a recent analysis by The New York Times Real Estate Section, incorporating flexibility and sustainable solutions adds long-term value to residential investments.

Smart Home Integration

The adoption of smart home technology has moved from novelty to necessity in many residential markets. Integrated systems for lighting, climate control, and security deliver unparalleled convenience and can significantly reduce energy consumption. Many buyers expect to see smart thermostats, remote-controlled appliances, and app-based monitoring as standard features. Not only do these technologies streamline everyday living, but they also enhance security and create personalized comfort tailored to each occupant.

Remote Work and Home Office Spaces

The remote work revolution has made dedicated office spaces a central consideration for homebuyers and renters. Flexible floor plans, soundproof rooms, and custom workstations are sought-after features in both new builds and renovation projects. Developers are also introducing multipurpose rooms and modular furnishings, allowing for adaptation as working styles continue to shift. This reflects a broader trend of homes built to serve diverse professional and personal needs without compromising on comfort or style.

Sustainable Building Practices

Growing awareness of climate change and rising utility costs has made sustainable building practices a top priority. Developers now incorporate recycled materials, solar panels, advanced insulation, and other green building technologies. These efforts minimize environmental impact while providing residents with lower energy bills and healthier indoor environments. Additionally, sustainability certifications add tangible value to properties and attract eco-conscious buyers.

Co-Living Arrangements

As urban populations rise and real estate prices soar, co-living has emerged as a practical and social alternative, particularly for young professionals and digital nomads. These communities offer private living spaces coupled with shared kitchens, lounges, and recreational areas. Such arrangements not only provide cost savings and flexibility but also create networks of support for newcomers to a city or those seeking communal experiences.

Social Media’s Impact on Real Estate Marketing

Technology has revolutionized not just the homes themselves but also the way they are bought and sold. Real estate professionals harness platforms like Instagram, TikTok, and Facebook to create immersive virtual tours and reach wider audiences. Social media-driven marketing methods can increase visibility, generate buzz around listings, and enhance engagement with buyers, sellers, and industry partners. According to The Wall Street Journal Real Estate, these platforms now influence every stage of the transaction process, from discovery to negotiation.

Emphasis on Wellness Features

Health and wellness features now play a central role in modern residential design, as home buyers increasingly prioritize spaces that support balance and well-being. Dedicated home gyms, quiet meditation rooms, and spa-inspired bathrooms encourage daily exercise, stress reduction, and self-care. Designers are also emphasizing natural light, indoor plants, and seamless access to outdoor terraces to improve mood and air quality. Together, these elements create homes that nurture physical vitality and mental clarity for modern lifestyles.

Urban Verticalization

Vertical living solutions address limited space and the growing demand in busy metropolitan areas. High-rise residential towers maximize land use while offering premium amenities, panoramic city views, and close access to broader hubs and cultural destinations. Many developments incorporate shared features such as rooftop gardens, lounges, and fitness centers. These elements recreate aspects of suburban comfort within a smaller footprint, encouraging social interaction, convenience, and a strong sense of community in dense urban environments worldwide.

Conclusion

Modern real estate trends are driven by innovation, adaptability, and a deep understanding of changing consumer needs. From smart home integration and sustainable building practices to wellness-focused layouts and digitally powered marketing, these developments are redefining residential living. By staying informed and embracing these trends, buyers and industry stakeholders can navigate a rapidly evolving landscape and secure lasting value in their investments.

Blog

How Pipe and Valve Systems Keep Modern Industries Flowing Safely

In the intricate web of modern industry, pipe and valve systems are the unsung heroes, quietly ensuring the seamless, efficient, and safe transport of fluids and gases that power our world. Whether it’s oil in a refinery, steam for manufacturing, or clean water for municipal use, these systems are fundamental to keeping countless processes moving smoothly behind the scenes. The reliability of these essential components directly influences the productivity, sustainability, and safety of critical infrastructure. Companies such as Mattsco Supply Company, a leading industrial piping company Tulsa, OK, have played a pivotal role in this field, supplying high-quality piping solutions since 1975. Their commitment to innovation and service underlies much of the safety and efficiency seen in industries today.

The Backbone of Industrial Operations

Pipes and valves function much like the circulatory system in the human body: they direct, control, and regulate the flow of essential substances throughout industrial complexes. These systems, which carry chemicals, oil, gas, or water, are found at the core of power plants, refineries, food processing facilities, and healthcare institutions. Their careful design and the choice of materials are absolutely vital to withstand the sometimes extreme pressures, temperatures, and chemical characteristics of the transported media. For instance, specialized alloys and polymers might be chosen to resist corrosive chemicals or intense heat.

Advancements in Materials and Technology

Materials science has greatly enhanced the scope of piping and valve applications. Traditional materials, such as steel, iron, brass, and copper, have been supplemented or even replaced with advanced plastics and composite materials. Among the most prominent innovations is Unplasticized Polyvinyl Chloride (UPVC), valued for its combination of strength, chemical resistance, and lightweight structure. UPVC valves and piping components have revolutionized fluid control, enabling faster installations, reducing maintenance costs, and ensuring longer operational life, especially in corrosive chemical environments. Their resistance to scaling and fouling also makes them ideal for potable water and food industries, where cleanliness and purity are paramount. Furthermore, the flexibility and modularity of modern fittings enable easier system expansion and modification, supporting the dynamic needs of industrial operations.

Integration of Smart Technologies

The digital transformation sweeping across industries has fully reached the world of pipe and valve systems, ushering in a new era of automation and intelligence. The incorporation of Internet of Things (IoT) technology into these systems has fundamentally changed how industries approach system reliability and risk management. Smart sensors, embedded throughout the piping network, continually monitor parameters such as pressure, temperature, and flow rates. Data from these sensors can be analyzed in real time, providing operational teams with instant alerts when readings move outside safe thresholds. As a result, issues such as leaks, blockages, or abnormal wear can be identified and addressed before they escalate into more costly problems. Predictive maintenance, powered by advanced analytics and machine learning, enables companies to schedule servicing only when it is truly needed, reducing routine shutdowns and significantly lowering the risk of unplanned downtime. Ultimately, this integration of smart technology enhances operational efficiency and workplace safety, resulting in significant time and resource savings throughout a system’s lifecycle.

Importance of Regular Maintenance

No matter how advanced the technology or material, all pipelines and valves require routine inspection and thoughtful maintenance. Over time, natural wear and tear, exposure to harsh substances, and mechanical stress can compromise the integrity of these systems. Regular maintenance, including cleaning, lubrication, and periodic replacement of worn components, helps identify emerging issues before they lead to leaks or catastrophic failures. Valves, in particular, are critical because they directly control fluid flow and pressure and must remain responsive and tight-sealing. Neglecting maintenance not only risks significant operational disruptions but can also pose serious safety hazards, threatening both workers and the environment. For this reason, many industries invest in comprehensive maintenance programs that use both traditional physical inspections and remote monitoring data to keep their systems in peak condition year-round, thus extending equipment lifespan and maintaining regulatory compliance.

Ensuring Safety and Compliance

Industrial piping and valve systems are subject to a host of regulations and standards, designed to protect workers, communities, and natural resources from potential hazards. Adhering to these standards, whether set by industry organizations, government bodies, or international agencies, is a non-negotiable aspect of system design, installation, and operation. For businesses, compliance ensures that their systems are robust enough to handle industry-specific demands, from volatile chemicals in chemical plants to sanitary requirements in food processing. The consequences of non-compliance can be severe, including legal penalties, environmental damage, or the loss of business licenses. Moreover, prioritizing safety and regulatory compliance also builds trust with customers and the public, cementing a company’s reputation as a responsible industry leader.

Conclusion

Pipe and valve systems remain the fundamental infrastructure that enables the safe, efficient operation of the world’s most vital industries. Through continued advancements in materials science and smart technologies, these systems have become safer, more reliable, and easier to maintain than ever before. Companies that commit to regular maintenance, rigorous safety protocols, and compliance with ever-evolving industry standards will ensure that their piping networks not only keep pace with technological change but also continue to safeguard workers, communities, and the environment. The future of industry depends on the invisible work of pipes and valves, and the ongoing innovation and care invested in their design and upkeep.

Blog

How Digital Payment Solutions Are Changing the Way Businesses Manage Spending

The Shift Towards Digital Payments

In recent years, businesses of all sizes have accelerated the move away from traditional payment methods. The urgency for quicker, more secure, and more efficient ways to handle transactions has driven this change. Companies are replacing paper-based systems and manual processes with agile digital tools to keep up with evolving market demands. Startups and established enterprises alike are exploring more innovative options for expense management, including startup credit cards, which enable rapid, trackable spending.

Digital payment adoption is no longer seen just as a way to modernize bookkeeping but as a strategic lever to unlock business growth. According to a J.P. Morgan report, well over half of its global clients named the ability to support new business models through digital treasury operations as a leading priority. Swift, digitized payments create new opportunities for companies to improve their spending oversight and support organizational scalability (source).

As digital payment platforms become mainstream, their role in eliminating cash handling and paper checks is impossible to ignore. In addition to speeding up transactions, businesses adopting digital payment solutions gain deeper visibility into every outgoing dollar. Account teams can quickly reconcile payments, manage vendor relationships, and meet compliance obligations with far less manual intervention. These capabilities are essential for industries that have historically faced slow-moving payment cycles and cumbersome expense reporting.

Beyond convenience, digital payments reflect the expectation that business systems deliver transparency and flexibility. This shift is not limited to one sector. Companies across retail, healthcare, manufacturing, and technology stand to benefit from fully embracing digital payment workflows.

Enhanced Security Measures

Security is a primary reason businesses are prioritizing digital payment solutions. Unlike traditional checks or physical cash, digital payment platforms are typically equipped with multi-factor authentication, data encryption, and fraud detection tools. Real-time validation of account details helps ensure that funds reach intended recipients, reducing the risk of criminal activity. Many platforms also include customizable user permissions, so only authorized personnel can initiate or approve transactions.

With cyber threats continually evolving, best-in-class digital payment providers invest heavily in next-generation security protocols. Businesses adopting such solutions gain peace of mind while also simplifying compliance with regulatory standards. For example, automated audit trails and secure records make it easier to demonstrate appropriate financial controls during an external review or audit. According to PYMNTS, digital transformation is rapidly reshaping how financial services mitigate risk and prevent fraud.

Integration with Financial Management Tools

Beyond simple payment processing, leading digital solutions integrate directly with accounting, budgeting, and enterprise resource planning software. This convergence gives finance teams real-time access to data across accounts payable, expense management, and payroll functions. When companies connect digital payments to their broader financial management ecosystem, they gain the power to streamline reconciliation, automate reporting, and boost budgeting accuracy.

Automated alerts and dashboards enable businesses to monitor spending patterns in real time, surface unusual activity, and track budget adherence down to the department or project level. Many platforms also allow for customizable spending rules, enabling greater control over where and how funds are allocated. This proper integration offers organizations a significant advantage in forecasting expenses, understanding cash burn, and planning for future investment.

Cost Savings and Improved Cash Flow

One of the most significant advantages of digital payment solutions is their impact on operational efficiency and the bottom line. Companies can reduce costs associated with printing, mailing, and reconciling paper checks, all of which are labor-intensive and can be prone to error. Faster electronic payments also allow businesses to capture early-payment discounts offered by vendors or to improve their ability to negotiate favorable payment terms.

Quick, reliable cash flow is an essential ingredient for business health. Digital payments shorten the transaction cycle, so companies can access incoming funds sooner and allocate resources more strategically. These improvements often translate into fewer delays in supplier payments, better vendor relationships, and less administrative stress on finance personnel. As reported by Comerica, businesses that embrace a range of modern payment options are more likely to maintain resilient and predictable cash flow.

Adapting to Consumer Preferences

The rise of digital payment methods is not only a back-office revolution. It mirrors changing consumer expectations, who now demand fast, flexible, and secure options for completing transactions. Businesses that offer digital payments can deliver a superior customer experience, thereby driving loyalty and repeat business. Providing a range of payment options, including mobile wallets, contactless cards, and online invoicing, broadens the potential customer base and meets users where they prefer to transact.

The ability to process digital payments quickly and securely at checkout is particularly valuable for e-commerce and retail. Swift transaction experiences reduce friction, minimize abandoned carts, and build customer confidence in a brand’s ability to safeguard their financial information.

Challenges in Transitioning to Digital Payments

The journey to fully digital payments has its hurdles. Upfront investments in technology, configuring new systems, and staff training all present initial barriers for businesses making the transition. In some industries, legacy workflows and outdated infrastructure can slow down migration efforts. However, with forward-looking planning and support from experienced vendors, organizations can minimize disruptions and realize long-term benefits that significantly outweigh these short-term challenges.

Another consideration is the readiness of partners and suppliers. Not all vendors are equipped to accept digital payments immediately, so businesses must coordinate closely to avoid bottlenecks during implementation.

Future Trends in Digital Payments

As technology evolves, so do the features and functionalities of digital payment solutions. Digital wallets continue to grow in popularity, enabling both consumers and businesses to store payment information and initiate transactions instantly and securely. Artificial intelligence and machine learning are also being leveraged to deliver more advanced fraud detection, automate reconciliation, and predict spending trends.

As regulatory environments change and fintech innovation accelerates, staying up to date on new developments is critical. Businesses that keep a finger on the pulse of digital payment trends are better positioned to adapt quickly, capitalize on advances, and remain competitive in their industries.

Conclusion

In today’s fast-paced financial environment, digital payment solutions offer far more than convenience. They enable companies to manage spending with greater precision, reduce risks, and prepare for long-term growth. The capabilities gained from embracing these technologies mean that businesses not only improve their day-to-day operations but also strengthen their foundation for the future. Those who adapt and innovate with digital payments are best poised to lead in the years ahead.

-

Technology11 months ago

Technology11 months agoRevealed: 8093642079 – Find Out Who’s Behind the Number

-

Business7 months ago

Business7 months agoHow Horseback Adventures Foster Connection and Wellness

-

Technology1 year ago

Technology1 year agoRaterpoint: Revolutionizing Online Content Evaluation and Feedback

-

Technology1 year ago

Technology1 year agoDetecting AI-Generated Text: Tips and Techniques

-

Technology1 year ago

Technology1 year agoFDXMZ24: A Comprehensive Guide

-

Entertainment1 year ago

Entertainment1 year agoFappelo: How to Engage with This Exciting New Phenomenon

-

Technology1 year ago

Technology1 year agoPerchance AI | Intelligent AI Solutions for Your Business

-

Blog1 year ago

Blog1 year agoBunkralbum: What You Need to Know About This Intriguing Concept